Product rinsing station, from where contaminated water flows into the settling tank

photo by BRUK Sp. z o.o.

Good practices and investments related to Cleaner Production

Example No. 32

Closing the water cycle on the production line by setting up a water retention and reuse system

Company:

BRUK Sp. z o.o., Czyżowice

Industry branch: Construction industry

Main products: paving stones and slabs, decorative concrete elements, concrete fences and architectural concrete furniture

Resources in question:

- Water

- Wastewater

Cost (implementation of good practice): Medium

The change described here relates to an existing installation used to

collect sludge generated from the production of the so-called “washed”

paving stones, i.e. paving stones and slabs, the top layer of which is

washed with water in a special way to give them a suitable appearance

(presented in the photo in the header of this description).

The basis of this system is a settling tank that collects the coarsest sludge fractions, and tanks built into the ground where finer sludge is collected along with contaminated water from production.

Originally, the tanks were emptied by a septic tank service company when necessary due to overfilling of the tank. Over time, the system was retrofitted with a water filtration and sludge dewatering node, allowing water to be recovered for the production process. However, due to the characteristics of concrete sludge and the increasing scale of production, this system proved to be insufficient and unreliable, resulting in the use of only mains water for concrete mixes.

The basis of this system is a settling tank that collects the coarsest sludge fractions, and tanks built into the ground where finer sludge is collected along with contaminated water from production.

Originally, the tanks were emptied by a septic tank service company when necessary due to overfilling of the tank. Over time, the system was retrofitted with a water filtration and sludge dewatering node, allowing water to be recovered for the production process. However, due to the characteristics of concrete sludge and the increasing scale of production, this system proved to be insufficient and unreliable, resulting in the use of only mains water for concrete mixes.

Applied solution:

As part of the Cleaner Production Project, the aforementioned system was expanded to include the ability to collect rainwater in tanks, and its operation was improved to allow the use of rainwater and filtered water from the production process (for concrete production). Thus, it was made possible to reuse collected water on the production line.

Obtained benefits and effects of the implementation:

- Reduction in the consumption of water drawn from the water mains by about 2,000 m3/year (i.e., by about 30%)

- Savings of about PLN 11,919 per year (payback period: about 1 year)

- Raising the environmental awareness of the company's employees

Water supply pipeline from underground tanks to concrete mixer

photo by BRUK Sp. z o.o.

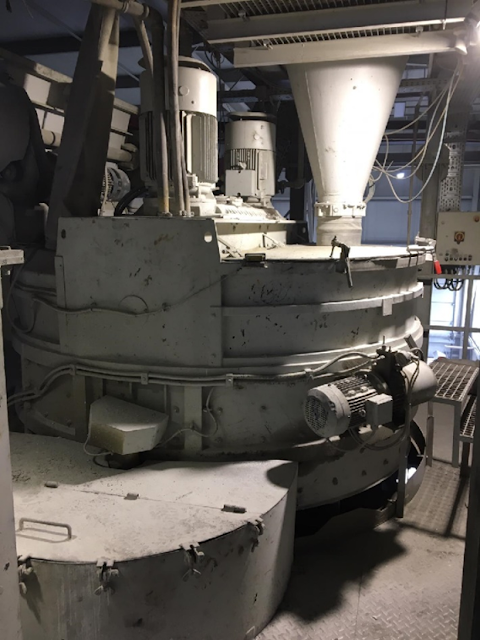

Concrete batching plant mixer, where water for concrete production is supplied from underground tanks and water mains

photo by BRUK Sp. z o.o.

Sources:

- Report on the Cleaner Production Project No. 49.791, developed within the framework of the Cleaner Production Academy at BRUK Sp. z o.o.: "Closing the water cycle on the MASA line by setting up a water retention and recycling system"

- Materials (including photos) submitted by BRUK Sp. z o.o.

Polish version:

This

material has been subsidized by the National Fund for Environmental

Protection and Water Management. The Polish Cleaner Production Movement

Association is solely responsible for its content.

0 komentarze :

Prześlij komentarz